ADC Connection Solutions

Innovative Bushing System for Rotor Blade Connections in Wind Turbines

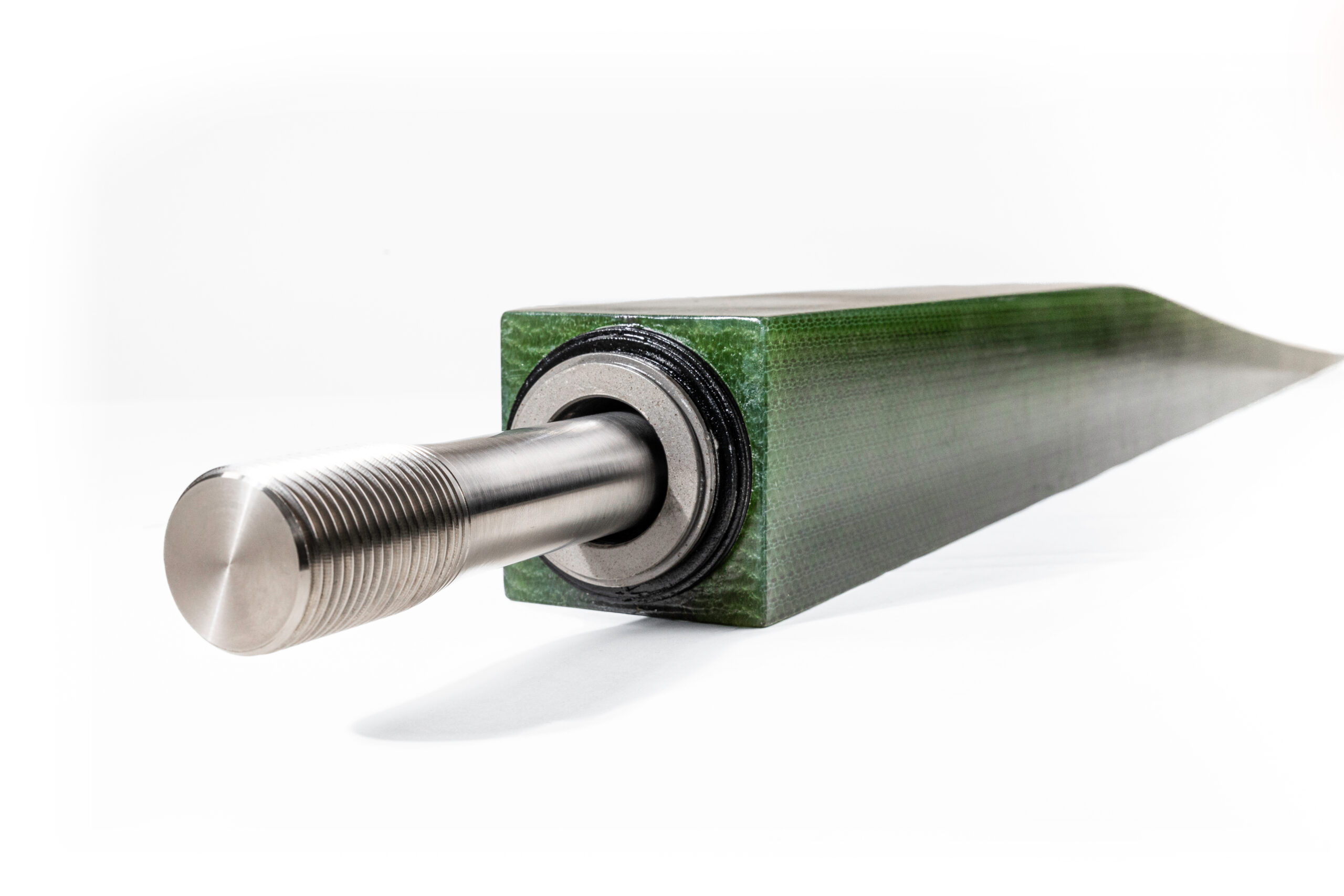

The ADC.Wedge

Joining components made of materials with significantly different stiffnesses presents a major challenge in achieving effective load transfer. This issue is particularly critical for rotor blade connections in wind turbines, where glass fiber composites must be joined to steel components. Current market solutions vary in effectiveness, often failing to achieve optimal performance and process reliability.

Extensive testing has validated our theoretical development process, advancing the ADC.Wedge from prototype to certification status, paving the way for practical application.

The Installation Process

ADC.Wedge M36 - now available

The resulting rotor blade connection is distinguished by its exceptional strength and durability, combined with low weight and high quality reliability. This innovation not only enables smaller connection diameters but also facilitates the realization of segmented rotor blades, meeting the growing demand for longer rotor blades.

Strong

Certified Pullout Force

(95 % confidence) 1120 kN

Max. Pullout 1320 kN

Durable

Fatigue Resistance

358 kN @ 5e6

m (< 5e6) = 10.7 , m (> 5e6) = 17

Low weight

9.5 kg installation-ready

Compact

78 x 78 x 1200 mm with low gradient slope for better load trasfer to shell layup

Tested

Countless testings in all variations at accredited test institute

Certified

by UL Solutions

Datasheet

| M24 | M30 | M36 | M42 | ||

|---|---|---|---|---|---|

| Length over all | mm | 900 | 1000 | 1200 | 1400 |

| Pullout Force (95% confidence) | kN | 510 | 760 | 1120 | 1350 |

| Height incl. Covering Layers | mm | 72 | 90 | 108 | 128 |

| Width = Height | mm | 52 | 64 | 78 | 92 |

| Thickness of Covering Layers each | mm | 10 | 13 | 15 | 18 |

| Mass Wedge built-in ready | kg | 3.2 | 5.4 | 9.5 | 15.5 |

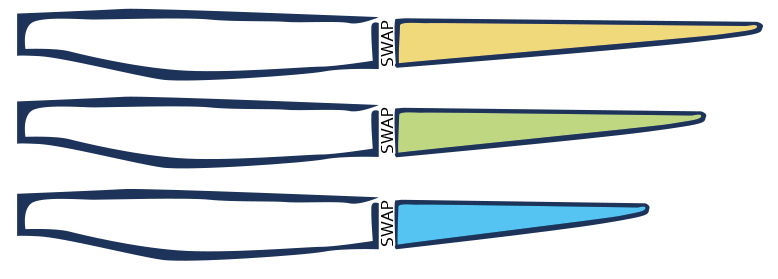

ADC.Wedge for Sectional Rotor Blades

The blade-to-blade connection is achieved using the ADC.Wedge Size M24 in combination with the ADC.SWAP joint and pretension system, offering the following advantages:

Unmatched load transmission

High-precision pretension

Easy tightening process

No special tools required

No face milling of the connecting surfaces

Only 3.9 kg per connection

Maintenance-free but releasable

ADC.Wedge as a Repair Solution for Defect Root Bushings

1. Cut out damaged bushing segment

2. Mount ADC.Wedges using bolts

3. Overlaminate Wedges with intact root section

Concept Advantages

- Easy Handling

- High level of prefabrication

- No special tooling required

- Reliable and well-proven bonding

About Us

ADC Connection Solutions GmbH, a spin-off of Aero Dynamik Consult GmbH, has reimagined the rotor blade root and split-blade connection to meet the demands of the constantly increasing rotor diameter and rotor blade loads.

Among our standout products is the ADC.Wedge, an innovative steel bushing system, which enables secure and reproducible bonding of the steel component with the composite material through vacuum infusion.

Strict adherence to all recommended bonding practices in the literature and the use of an enhanced resin formulation results in our excellent bonding properties.

The ADC.Wedge is offered as a ready-to-use solution, making it easy to integrate into the rotor blade.

Contact

info@adc-connection-solutions.de